An rising requirement for reliable energy alternatives has resulted to the widespread application of SF6, or SF6, in power systems. This potent GHG is recognized for its remarkable thermal insulation features, but it presents considerable environmental hazards when ruptures take place. For this purpose, SF6 leak detection has become a vital part of maintaining infrastructure in energy production and delivery. To efficiently identify these leaks, technicians utilize state-of-the-art methods, particularly SF6 leak detection devices.

Such specialized devices are designed to identify the otherwise unseen gas, providing a visual depiction of escapes that can often go undetected by conventional methods. Grasping how these devices work not only underscores their importance in ensuring safety but also underscores their importance in safeguarding the environment. By leveraging new technology, operators can rapidly locate and resolve leaks, ultimately aiding to reduce the negative effects of SF6 on our environment.

The Way SF6 Gas Detection Cameras Work

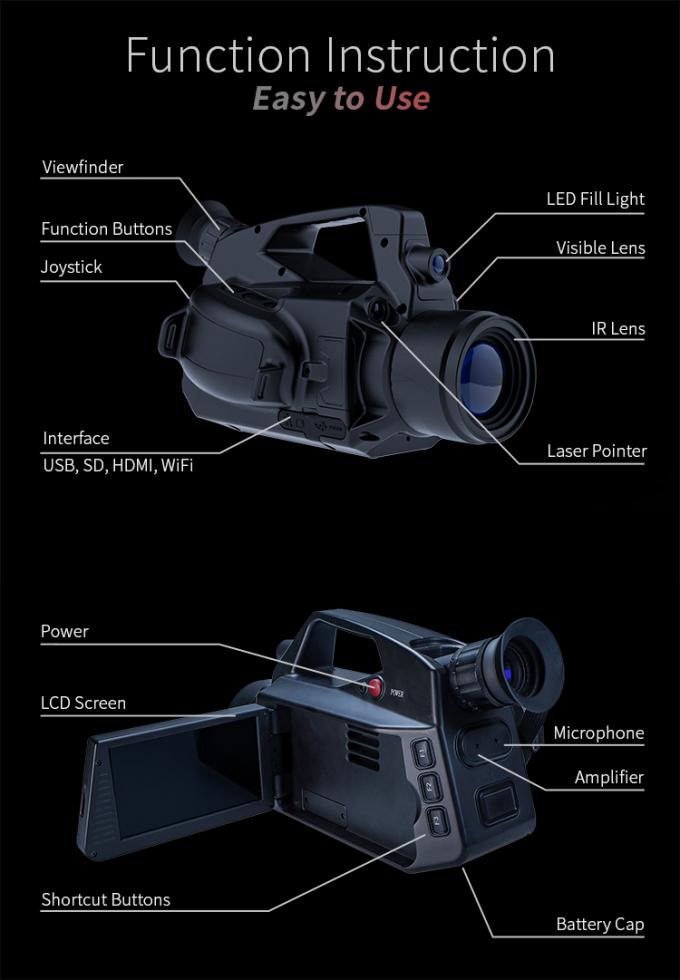

SF6 leak detection cameras use cutting-edge infrared technology to identify sulfur hexafluoride leaks in different environments. These cameras are specifically designed to detect the distinct thermal signature emitted by SF6 gas. When a leak occurs, the gas spreads and can be visualized using the camera, which captures the unique absorbent properties of the infrared light wavelength associated with SF6.

The cameras function by employing an infrared sensor that can measure the concentration of sulfur hexafluoride in the air. By analyzing the infrared radiation emitted from the environment, the camera can differentiate between SF6 and alternative gases. When a user points the camera towards a suspected leak, it shows a visual representation that marks areas with higher concentrations of the gas. This enables users to quickly and precisely pinpoint the exact location of the leak.

In addition to capturing images, numerous SF6 gas leak detection cameras also offer real-time data analysis and reporting features. This functionality improves the efficiency of leak detection, enabling technicians to monitor changes in gas concentration over time. The combination of thermal imaging and sophisticated software ensures that businesses can maintain safety standards and regulatory compliance while reducing the environmental impact of sulfur hexafluoride emissions.

Applications of SF6 Leak Detection

SF6 leak detection cameras are chiefly used in the power industry to locate leaks in high-voltage circuit breakers, transformers, and other equipment that use sulfur hexafluoride gas. The insulating properties of sulfur hexafluoride make it a common choice for maintaining safe electrical environments; but its greenhouse gas potential means that any leaks must be detected and addressed swiftly. By employing an sulfur hexafluoride leak detection camera, technicians can visually pinpoint where the gas escape, guaranteeing that equipment operates efficiently and in compliance with environmental regulations.

In addition to this to the electricity industry, these cameras have applications in research and testing facilities. They are used to observe experimental setups that involve sulfur hexafluoride, helping scientists and engineers verify that their systems are sealed properly and functioning as intended. This feature is vital in avoiding the unintended release of SF6 during experiments and safeguarding both personnel and the environment.

Another notable application is in the inspection and maintenance of underground utilities and distribution networks. Sulfur hexafluoride is used in gas-insulated switchgear and various underground substations. Leak detection cameras provide a non-invasive means to monitor these installations, allowing for the early identification of leaks that could threaten system integrity and safety. Regular inspections using sulfur hexafluoride leak detection technology help utility companies maintain reliable service while minimizing their carbon footprint.

Benefits of Using SF6 Gas Leak Detection Cameras

One of the primary benefits of using SF6 leak detection cameras is their ability to detect leaks efficiently and successfully. Traditional methods of detecting gas leaks, such as gas sniffers or pressure testing, can be time-consuming and may not always locate the precise location of a leak. SF6 leak cameras provide immediate visual feedback, allowing technicians to see the gas emissions in real-time, leading to more efficient maintenance and minimized downtime in manufacturing settings.

Another important advantage is the increased safety provided by these cameras. SF6 is a highly effective greenhouse gas, and even minor leaks can have serious environmental impacts. By using an SF6 leak detection camera , companies can minimize emissions, comply with environmental standards, and ensure a more secure working environment for their employees. This proactive approach to leak detection helps in preserving both the Earth and the health of the workforce.

Additionally, SF6 leak cameras can lead to financial savings over time. By spotting and addressing leaks promptly, organizations can avoid the economic impacts associated with wasted gas, regulatory fines, and potential damages from environmental violations. Investing in this equipment not only promotes responsible environmental practices but also contributes to the bottom line by improving operational efficiency and resource management.